The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

Your reverse osmosis system was a star performer. Pressures were stable, flow rates were high, and water quality was perfect. Then, slowly but surely, things started to change. You find yourself needing to clean the membranes more often. The differential pressure is creeping up, and energy costs are rising.

Sound familiar? You’re likely dealing with the silent killer of RO performance: biofouling.

Biofouling is more than just a nuisance; it’s a costly problem that can shorten membrane life, increase operational expenses, and cause system-wide shutdowns. But here’s the kicker: it often happens in ways you wouldn’t expect. Let’s dive into the surprising reasons this stubborn bacterial slime takes over your system and how to fight back.

The Unexpected Culprits Behind Biofouling

Many operators assume biofouling only happens with obviously “dirty” water. The truth is more complex. Here are four common scenarios where biofouling can thrive, even in well-managed systems.

1. The “Clean Water” Trap (Systems with Long Shutdowns)

It seems counterintuitive, but systems running on high-quality feed water (like municipal tap water) are prime candidates for biofouling, especially after periods of downtime.

- The Problem: When a system sits idle, even for a weekend, the stagnant water inside becomes a perfect incubator. Any trace amounts of organic matter and bacteria, warmed by ambient temperatures (especially in summer), can multiply rapidly, forming a biofilm.

- The Symptom: You notice a significant drop in performance after starting the system back up from a shutdown. The first-stage pressure increases dramatically.

2. The Reclaimed Water Challenge (Wastewater Reuse Systems)

Using treated wastewater is an excellent sustainability practice, but it presents a high risk for biofouling.

- The Problem: Reclaimed water, even after secondary or tertiary treatment, often contains residual organic compounds—a veritable feast for microorganisms. If your pre-treatment system (like UF or MBR) has even a minor hiccup, you are essentially pumping a nutrient-rich smoothie directly to your RO membranes.

- The Symptom: Severe, hard-to-clean biofouling that seems to reappear almost immediately after a chemical cleaning cycle.

3. The Seawater Paradox (Desalination Systems)

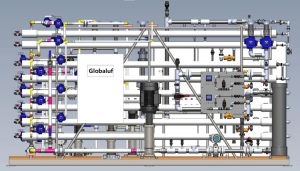

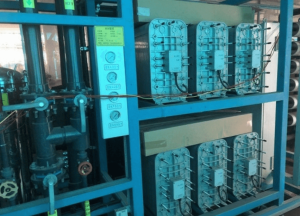

You’d think the constant, high-pressure operation of a Containerized SWRO System would keep things clean. However, seawater is a living ecosystem.

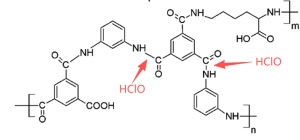

- The Problem: Seawater is full of algae and bacteria. While shock-dosing with biocides kills these organisms, their dead cells can break apart. The organic matter from these dead cells then flows downstream and becomes food for other slime-forming bacteria on the membrane surface.

- The Symptom: A rapid increase in differential pressure across the ultrafiltration pre-treatment and the first stage of the RO system, particularly within 3-4 hours of a chlorine shock dose.

4. The Chemical Conundrum (When Your “Solution” Becomes the Problem)

Sometimes, the chemicals you add to prevent problems can inadvertently cause biofouling.

- Incompatible Antiscalants: Some antiscalant formulations can act as a nutrient (containing phosphorus, for example), encouraging bacterial growth.

- Dechlorination Agents: Sodium bisulfite (SBS) is essential for removing chlorine to protect RO membranes. However, excess SBS can promote the growth of specific sulfate-reducing bacteria, leading to a nasty, slimy black fouling.

- Improper Biocide Use: Using the wrong biocide or an incorrect dosage can be ineffective and can even break down larger organic molecules into smaller, more easily digestible food for bacteria.

Fighting Back: The Globaluf Proactive Approach

Biofouling is a complex mix of microbiology and chemistry. A simple chemical cleaning is just a temporary fix; the key is a holistic, preventative strategy.

- Design from Day One: The fight against biofouling starts with smart system design. This means selecting the right pre-treatment technology for your specific water source and engineering the system to avoid “dead legs” or areas of low flow where water can stagnate.

- Smart Operational Protocols: Implement rigorous procedures for system shutdowns, including freshwater flushing and preservation protocols to prevent growth during idle periods.

- Monitor, Monitor, Monitor: Don’t wait for the alarm bells. Regularly track your normalized flow rates, pressures, and conductivity. A gradual negative trend is the earliest warning sign of fouling and allows you to act before it becomes a crisis.

- Choose Your Chemicals Wisely: Work with experts to ensure your antiscalant, biocide, and other chemical programs are compatible and optimized for your feed water. Learn more about best practices from industry leaders like the American Water Works Association (AWWA).

Biofouling doesn’t have to be an inevitable part of running an RO system. With the right design, operation, and expert guidance, you can keep your membranes clean and your system running at peak performance.

Struggling with stubborn biofouling in your system? The experts at Globaluf are here to help. Contact us at sales@globaluf.com to discuss a solution tailored to your needs.

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf

Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance

Comprehensive Guide to EDI System Maintenance: Effective Cleaning Techniques and Prevention Strategies

Key Parameters at RO Feed Water – The First Line of Defense in RO Desalination