The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

What is RO Membrane Oxidation?

Think of RO membrane oxidation as a chemical burn. TFC membranes, the standard for modern RO systems, have an ultra-thin polyamide layer responsible for salt rejection. This layer is extremely sensitive to strong oxidizing agents.

The most common culprit is free chlorine, which is widely used in municipal water supplies for disinfection. While vital for public health, even trace amounts of chlorine (as low as 0.1 ppm) can cause rapid and irreparable damage to the membrane. Other oxidants include chloramines, ozone, and potassium permanganate.

When oxidation occurs, the chemical structure of the polyamide layer is broken down, leading to microscopic tears and holes.

How to Diagnose Chlorine Attack?

Unfortunately, oxidation damage is permanent. You can’t clean or repair an oxidized membrane. That’s why early detection and prevention are critical. Here are the classic symptoms of chlorine attack:

- Increased Salt Passage: This is the most definitive sign. The membrane loses its ability to reject dissolved solids, resulting in higher conductivity (or TDS) in your permeate (product water). Your water quality plummets.

- Increased Permeate Flow: Counterintuitively, a damaged membrane will often produce more water at the same feed pressure. This is because the “holes” created by oxidation reduce the membrane’s natural resistance to flow.

- No Recovery with Cleaning: Unlike fouling or scaling, which can be resolved with membrane cleaning, oxidation damage is irreversible. If a CIP (Clean-In-Place) procedure doesn’t improve performance, oxidation is a likely cause.

The Gold Standard: Proactive Strategies for Preventing Membrane Oxidation

The only effective cure is prevention. Protecting your RO membranes requires a robust dechlorination strategy implemented in the pretreatment stage, before feed water ever reaches the high-pressure pump. There are two primary, industry-proven methods.

Method 1: Chemical Dechlorination with Sodium Metabisulfite (SMBS)

The most common method for dechlorination is injecting a chemical reducing agent, typically Sodium Metabisulfite (SMBS), into the feed water. SMBS rapidly neutralizes free chlorine, rendering it harmless to the membranes.

- How it Works: SMBS is dosed continuously using a chemical injection pump. The dosage is controlled and monitored using an Oxidation-Reduction Potential (ORP) sensor. A healthy ORP reading for RO feed water should be below +200 mV.

- Pros: Highly effective, relatively low capital cost, and precise control via ORP monitoring systems from brands like Hach.

- Cons: Requires ongoing purchase and handling of chemicals. Overdosing can contribute to biological fouling on the membranes.

Method 2: Physical Adsorption with Granular Activated Carbon (GAC) Filters

Another excellent method is passing the feed water through a media filter containing Granular Activated Carbon (GAC).

- How it Works: GAC removes chlorine through a process of catalytic adsorption. As water flows through the carbon bed, chlorine reacts with the carbon and is converted into chloride ions. Ensuring sufficient Empty Bed Contact Time (EBCT)—typically 3-5 minutes—is crucial for effective removal.

- Pros: Eliminates the need for chemical handling, simple operation.

- Cons: Higher initial capital cost. Carbon has a finite lifespan and needs periodic replacement. GAC beds can also become a breeding ground for bacteria if not managed properly.

The Best of Both Worlds: A Multi-Barrier Approach

For critical applications where reliability is non-negotiable, the most robust design combines both methods. A GAC filter serves as the primary dechlorination step, removing the bulk of the chlorine. A downstream SMBS injection system acts as a polishing step and a fail-safe, protecting the membranes in case of GAC exhaustion or system bypass.

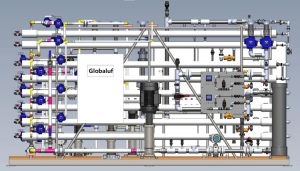

This multi-barrier philosophy is at the core of how we design our Globaluf Reverse Osmosis Systems, ensuring maximum protection and peace of mind for our clients.

Partnering for Longevity: Your System Design Matters

Preventing membrane oxidation isn’t just about adding a single component; it’s about intelligent system design from the ground up. A reliable RO plant incorporates:

- Proper Pretreatment: A comprehensive pretreatment train that includes effective dechlorination is the first line of defense.

- Advanced Monitoring: Real-time ORP monitoring and alarm systems that can shut down the system if chlorine is detected.

- Quality Components: Utilizing high-quality membranes from industry leaders like DuPont FilmTec™ or Hydranautics, which are built to specification but still require protection.

At Globaluf, we don’t just sell equipment; we deliver reliable, long-term water treatment solutions. Our engineering team designs every RO system with built-in safeguards to protect your most critical assets.

Protect Your Investment. Ensure System Reliability.

Don’t let a preventable issue like membrane oxidation compromise your operations. Whether you are an OEM looking for a robust design or an end-user needing a reliable water supply, proactive protection is key.

Our team of experts can audit your existing system or design a new one with a bulletproof dechlorination strategy.

Contact Mary at sales@globaluf.com or visit our website at www.globaluf.com to schedule a free consultation and ensure the longevity of your RO system.

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf

Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance