Comprehensive Guide to EDI System Maintenance: Effective Cleaning Techniques and Prevention Strategies

Introduction

Electrodeionization (EDI) technology stands as a cornerstone of modern ultrapure water production. For industries from pharmaceuticals to power generation, EDI systems—powered by industry-leading modules from brands like IONPURE and Veolia (E-CELL)—deliver the consistent, high-purity water essential for critical processes, all without the use of hazardous chemicals.

However, like any high-performance engine, an EDI system requires expert care to maintain its efficiency and longevity. Neglecting maintenance doesn’t just reduce performance; it risks costly production downtime, irreversible module damage, and compromised water quality.

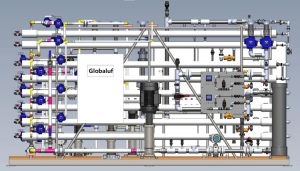

At Globaluf, we are not just system integrators; we are your partners in performance. This guide shares our expertise in EDI system maintenance to help you protect your investment and ensure uninterrupted operations.

Why Proactive EDI Maintenance is Non-Negotiable

For an Engineering Director like Isabel at a large food & beverage group, unexpected downtime is a non-starter. For a Procurement Director like John at an OEM, ensuring the long-term reliability of the equipment they sell is paramount to their brand’s reputation. Proactive maintenance directly addresses these needs by:

- Protecting Your Investment: EDI modules are a significant capital expense. Proper care prevents premature failure and maximizes their operational lifespan.

- Ensuring Consistent Water Quality: Regular maintenance prevents the gradual decline in product water resistivity, ensuring it consistently meets stringent standards (e.g., 18 MΩ·cm).

- Preventing Costly Downtime: A scheduled cleaning is far less disruptive and expensive than an emergency shutdown caused by severe scaling or fouling.

- Optimizing Energy Consumption: A clean, efficient system operates with lower electrical resistance, reducing overall energy costs.

Key Indicators: When Does Your EDI System Need Cleaning?

The key to effective EDI system maintenance is monitoring performance data. You should schedule a cleaning or diagnostic service when you observe:

- Increased Electrical Resistance: A steady increase in the EDI module’s electrical resistance indicates that ion migration is becoming more difficult, often due to mineral scale buildup.

- Increased Differential Pressure: A rising pressure drop between the module’s inlet and outlet points to physical blockages from suspended solids, biofouling, or severe scaling.

- Decreased Product Water Quality: If the final water resistivity begins to drop, it’s a clear sign that the EDI module is losing its purification efficiency.

- Reduced Product Flow Rate: A decline in the design flow rate, while holding pressures constant, suggests internal fouling.

Expert Tip: Daily data logging is the most powerful tool for predictive maintenance. Consistent records allow trends to be spotted early, long before they become critical problems.

The Science of Cleaning: Tailored Techniques for Common Foulants

As integrators of premier systems using IONPURE and E-CELL modules, we follow manufacturer-recommended procedures tailored to the specific foulant.

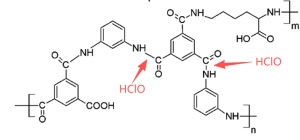

- For Mineral Scaling (Hardness): Low pH Cleaning

- Cause: Primarily caused by calcium and magnesium carbonate precipitates, especially if the upstream RO system’s anti-scalant treatment is failing.

- Solution: A carefully controlled recirculation of a low-pH cleaning solution (e.g., citric acid) is used to dissolve the scale without damaging the membranes or resin.

- For Organic & Biological Fouling: High pH Cleaning

- Cause: Biofilms, bacteria, and organic matter can accumulate within the module, creating slime and impeding flow.

- Solution: A high-pH cleaning regimen, often using a combination of sodium hydroxide and a brine solution, effectively breaks down and removes organic and biological foulants.

WARNING: The Risks of Improper Cleaning DIY cleaning is fraught with risk. Using the wrong chemical, incorrect concentrations, or improper temperatures can cause irreversible oxidation damage to the ion-exchange membranes, rendering the module useless. This is not a simple process and should be performed by a trained professional.

Prevention is Better Than Cure: Strategies to Extend EDI Lifespan

The most effective maintenance strategy is prevention.

- Upstream RO Performance: The health of your EDI system is directly dependent on its feed water. Ensure your RO pre-treatment system is impeccably maintained to provide high-quality, low-fouling potential water.

- Correct Operating Procedures: Follow correct startup and shutdown sequences to prevent issues like water hammer or air pockets, which can damage modules.

- Scheduled Professional Audits: Engage a service expert like Globaluf to perform regular system audits. We can identify subtle issues with the RO, feed pumps, or instrumentation that could impact your EDI’s long-term health.

Globaluf: Your Expert Partner for EDI System Integration & Service

At Globaluf, we specialize in designing, building, and maintaining robust EDI systems tailored to your exact needs. We leverage the world’s best components, including IONPURE and E-CELL modules, to deliver unparalleled performance.

Our services include:

- Custom EDI System Design and Integration

- Preventative Maintenance Plans

- On-Demand Professional Cleaning & Sanitization

- System Troubleshooting and Performance Audits

- OEM & End-User Support

Don’t wait for a problem to disrupt your production. Partner with an expert who can ensure your ultrapure water system operates flawlessly.

Contact Globaluf today to discuss your EDI system maintenance needs, or explore our range of custom-built EDI Systems to see what’s possible for your facility.

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf