Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Introduction

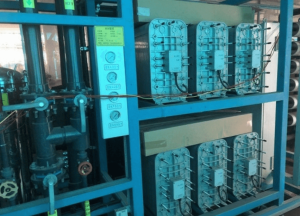

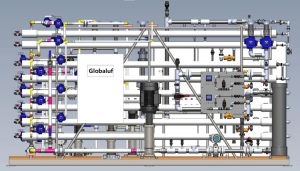

In the world of water treatment, reverse osmosis (RO) systems are essential for producing high-quality purified water. However, one common challenge that plagues these systems is RO membrane scaling. This phenomenon can significantly reduce efficiency, increase operational costs, and shorten the lifespan of your equipment. As a leading provider of advanced water treatment solutions at GlobalUF, we specialize in membrane-based technologies, including ultrafiltration and reverse osmosis equipment. In this blog post, we’ll dive deep into the causes of RO membrane scaling, its impacts, and proven prevention methods to help you maintain optimal performance.

Whether you’re an international OEM manufacturer like those partnering with brands such as Dupont or a large enterprise in the food and beverage sector, understanding RO membrane scaling is crucial for sustainable operations. Let’s explore this topic step by step.

What is RO Membrane Scaling?

RO membrane scaling occurs when insoluble salts, minerals, or other substances precipitate and accumulate on the surface of the reverse osmosis membrane. This buildup restricts water flow, increases pressure requirements, and ultimately leads to system inefficiencies. Common in applications like seawater desalination, wastewater reuse, and pure water production, scaling is often triggered by high concentrations of ions in the feed water.

At GlobalUF, our customizable RO systems are designed to minimize such issues through advanced pre-treatment options. For more details, check out our Reverse Osmosis Equipment.

Common Causes of RO Membrane Scaling

Understanding the root causes of RO membrane scaling is the first step toward effective mitigation. Based on extensive industry experience, here are the primary factors:

1. Inorganic Salt Scaling

Inorganic salts like calcium carbonate (CaCO3), calcium sulfate (CaSO4), and barium sulfate (BaSO4) are frequent culprits. When the feed water’s ion concentration exceeds solubility limits—often due to high recovery rates or inadequate pre-treatment—these salts crystallize on the membrane.

For instance, in regions with hard water, such as parts of the Middle East or North America, calcium-based scaling is prevalent. This is why pre-softening is vital.

2. Metal Oxide and Hydroxide Scaling

Metals like iron, aluminum, and manganese can oxidize and form hydroxides that deposit on membranes. This often happens when source water contains these elements and is exposed to oxidants during pre-treatment.

Famous brands like Hydranautics and Toray emphasize the importance of iron removal in their RO membrane guidelines to prevent such issues.

3. Colloidal and Particulate Scaling

Colloids, silt, and organic matter can form a gel-like layer on the membrane, exacerbating RO membrane scaling. High silt density index (SDI) values in feed water are a red flag, commonly seen in surface water sources.

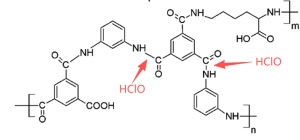

4. Biological Fouling Contributing to Scaling

While not direct scaling, microbial growth can create biofilms that trap scaling agents. In warm climates like Southeast Asia, this is a significant concern for RO systems.

5. Operational Factors

Improper system design, such as excessive recovery rates (over 75% without antiscalants), fluctuating pH, or temperature variations, can accelerate RO membrane scaling. For example, higher temperatures reduce salt solubility, promoting precipitation.

Our experts at GlobalUF recommend regular monitoring; explore our Membrane Water Treatment Solutions for integrated monitoring features.

The Impact of RO Membrane Scaling on Your Operations

RO membrane scaling doesn’t just affect the membrane— it ripples through your entire water treatment process:

- Reduced Permeate Flow: Scaling blocks pores, forcing higher pressures and energy consumption.

- Increased Maintenance Costs: Frequent cleaning or membrane replacement can add up, especially for large-scale operations like those in food processing plants.

- Compromised Water Quality: Scaling leads to higher salt passage, failing to meet standards for pure water or desalination.

- Downtime Risks: Severe cases require system shutdowns, impacting production lines.

Effective Prevention and Control Strategies for RO Membrane Scaling

Preventing RO membrane scaling requires a multi-faceted approach. Here’s how you can safeguard your system:

Pre-Treatment Optimization

- Implement robust pre-treatment to remove scaling precursors:

Softening and Ion Exchange: Reduce calcium and magnesium ions. - Ultrafiltration (UF) Integration: Filter out colloids and particulates before RO. Visit our Ultrafiltration Equipment for customizable options.

- pH Adjustment: Maintain optimal pH (typically 6-8) to prevent carbonate scaling.

Antiscalant Dosing

Use chemical antiscalants to inhibit crystal formation. Dosage depends on water analysis—our team can provide tailored recommendations based on your feed water profile.

Regular Cleaning and Monitoring

- Chemical Cleaning: Use citric acid or EDTA-based cleaners for inorganic scales.

- Monitoring Tools: Track differential pressure, SDI, and LSI (Langelier Saturation Index) to predict scaling risks.

- System Design Best Practices: Opt for low-fouling membranes from reputable suppliers like DuPont Water Solutions.

In middle-eastern desalination projects, combining these strategies has extended membrane life by up to 50%.

Advanced Technologies

For high-risk applications, consider hybrid systems like RO with nanofiltration or forward osmosis to dilute concentrates and minimize RO membrane scaling.

At GlobalUF, our OEM and ODM services ensure your equipment is built with these preventive measures in mind.

Conclusion: Partner with GlobalUF for Scaling-Free RO Systems

RO membrane scaling is a manageable challenge with the right expertise and equipment. By addressing causes through pre-treatment, monitoring, and advanced designs, you can ensure reliable, cost-effective water treatment.

Ready to tackle RO membrane scaling in your operations? Contact Us at sales@globaluf.com today for a free consultation on our top-quality, customizable water treatment plants. Visit www.globaluf.com to explore our full range of solutions and request a quote. Let’s optimize your water treatment process together!

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf

Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance