Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance

Foreword

For widely used desalination membranes like Nanofiltration (NF) and Reverse Osmosis (RO), membrane scaling is a universal concern. When scaling occurs in a desalination unit, antiscalants are often the primary suspect – questions arise about whether the dosage was sufficient or if the antiscalant performance was adequate.

However, the reality is that the causes of desalination membrane scaling are not limited to just the antiscalant. Fluctuations in system influent water quality, the operating recovery rate (concentration factor) of the unit, and the operational mode of the system are all critical factors contributing to scaling. Variations in these factors can similarly lead to severe inorganic salt scaling and fouling.

In the first half of 2025, a severe inorganic salt scaling incident occurred in the NF membrane system at a large coal-based new materials industrial park’s wastewater treatment plant for reclaimed water in Southern China, due to drastic water quality fluctuations. Fortunately, the issue was discovered promptly, and the system was successfully restored through rapid and thorough cleaning, a testament to the swift and effective maintenance provided by Globaluf.

This article aims to share this case study to help professionals prevent inorganic salt scaling in membrane systems and discover better solutions.

Project Overview

Centralized treatment of industrial wastewater is increasingly adopted across industrial parks in China. This approach significantly reduces capital expenditure for individual enterprises within the park, as they no longer need to build their own wastewater treatment systems. Furthermore, centralized treatment lowers operational and management costs for these factories. By engaging professional water treatment companies, centralized treatment can also elevate the overall discharge standards of the park’s wastewater, yielding both economic and environmental benefits.

The coal-based new materials industrial park in Southern China, established in 2016, leverages abundant local coal resources. Centered around a leading chemical enterprise, it has attracted six companies. The park primarily focuses on coal-based new chemical materials, chemical products, and the circular economy of coal and its by-products.

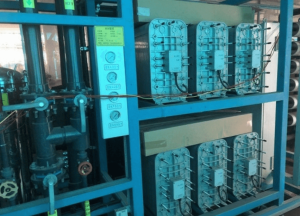

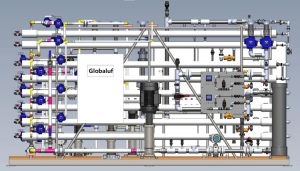

The park’s wastewater treatment and reclaimed water reuse project operates under a PPP model, managed and maintained by an environmental technology company under a state-owned enterprise. The project’s design capacity includes a 20,000 m³/d wastewater treatment plant and a 15,000 m³/d reclaimed water plant. Since its construction in 2017 and operation in 2018, it has primarily treated and reused industrial wastewater from the park.

System Process and Operational Status

The system process flow is as follows:

The wastewater treatment plant employs an A2O+MBR process, while the reclaimed water plant utilizes an NF (Ultra-low Pressure Selective Nanofiltration Membrane) filtration process. The NF unit in this project specifically utilizes DuPont NF270-400 nanofiltration membranes (for more information, visit DuPont Water Solutions).

Industrial wastewater, after passing through a fine screen, enters the equalization tank. From there, it is pumped to the mechanical accelerated clarifier, then proceeds through the hydrolysis acidification tank to the biological treatment unit. The biological section features an AOA process (Anoxic + Aerobic + Anoxic tanks). After treatment in the MBR membrane tank, the permeate flows into the NF system. The MBR membrane, a microfiltration membrane, effectively separates colloids and suspended solids from the water.

The reclaimed water station utilizes an NF process, which efficiently removes heavy metal ions, dissolved organic matter, colloids, bacteria, and viruses. The NF unit comprises 4 sets, each consisting of 246 membrane elements. Each set has a designed permeate flow rate of 156 m³/h and a designed recovery rate of 75%.

The effluent quality from the wastewater treatment plant meets the Class A standard of the “Discharge Standard of Pollutants for Urban Wastewater Treatment Plants” (GB18918-2002). The reclaimed water effluent quality adheres to the standards of the “Code for Design of Wastewater Reuse Engineering” (GB50335-2002).

Issues Encountered During System Operation

- Since December 2024, the influent water quality to the reclaimed water system experienced drastic changes. The conductivity increased from a minimum of 3200 μs/cm to a maximum of 4500 μs/cm, an increase of over 40%.

Figure 1: Conductivity Curve of Reclaimed Water System Inlet

- The drastic water quality change severely impacted the reclaimed water system, leading to significant fouling of the A# and C# NF units, which had recently been fitted with new membrane elements. The inlet pressure rapidly increased, and the inlet flow rate quickly decreased over a short period. The pressure and flow curves for A# NF are shown in [Figure 2: A# NF Inlet Pressure Curve] and [Figure 3: A# NF Inlet Flow Curve].

Figure 2: A# NF Inlet Pressure Curve

Figure 3: A# NF Inlet Flow Curve

- The permeate flow rate of the A# and C# NF units rapidly attenuated in a short period. Even after online CIP (Clean-In-Place) acid cleaning, the flow rate was difficult to restore. The operating parameters for A# and C# NF units after online cleaning are shown in Table 1.

Table 1, A# and C# NF Operating Parameters After Online Cleaning

- From Table 1, it is evident that the permeate flow rate of both A# and C# NF units rapidly declined from the design capacity of 156 m³/h to less than 80 m³/h, a decay exceeding 50%. This indicates severe fouling, and the membrane fouling could not be recovered through conventional online CIP cleaning.

- A disassembled inspection of the second stage membrane elements of A# NF revealed a large amount of inorganic salt scaling inside the membrane elements and at the inlet end face (Figure 4). This scaling severely blocked the inlet flow channels, which was the primary reason for the significant changes in NF unit inlet pressure, inter-stage pressure difference, and permeate flow rate.

Figure 4: Accumulation of foulants on the inlet end face of a nanofiltration (NF) second-stage membrane element before cleaning

- After draining the water from the second stage membranes, their weight was mostly between 24-25 kg. Compared to new wet membranes (wet weight 14.5 kg), the weight increased by nearly 10 kg, an increment of over 67%, indicating a significant amount of inorganic salt scaling and fouling within the membrane elements.

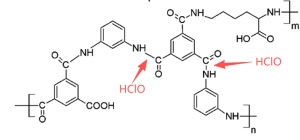

- Qualitative testing of the pollutant scale sample revealed a white inorganic salt scale (Figure 5), presenting as a powder with a distinct gritty texture. Based on its characteristics, it was preliminarily identified as carbonate scale.

Figure 5: A sample of white inorganic salt scale removed from a water treatment membrane system

- A qualitative test using hydrochloric acid on the scale sample showed a vigorous reaction with the acid, with the scale dissolving instantly and producing numerous tiny bubbles. This essentially confirmed it as carbonate scale. Furthermore, the cleaning solution monitoring report also indicated that the main component was CaCO3 (Table 2).

Table 2, Cleaning Solution Monitoring Report

- Although the B# and D# NF units had older membranes with longer service lives, showing some aging and cumulative fouling/relatively lower permeate flow rates, their permeate flow rates did not exhibit significant fluctuations during the same period. This indicates that these two NF units did not experience significant fouling during this time, implying that the cause of fouling in A# and C# NF units differed from B# and D# NF units.

- By comparing the operating data of all four NF units, it was found that there were significant differences in the operating recovery rates between the two new (A# and C#) and two old (B# and D#) membrane sets. On January 9, 2025, the A# and C# NF units had their membrane elements replaced. Since these were new membranes, their operating recovery rate was adjusted to the designed 75%. Coupled with a significant increase in influent water quality in January (inlet conductivity rose from 3200 μs/cm to 3800 μs/cm, peaking at 4500 μs/cm), the two newly replaced NF membranes experienced severe inorganic salt scaling. Both the qualitative analysis of the on-site scale sample and the cleaning solution analysis confirmed the inorganic scale to be carbonate. In contrast, the B# and D# NF units, due to their older membrane elements, had inherently lower operating recovery rates (around 50%) and thus did not experience significant scaling.

- Using the measured raw water quality and a designed NF recovery rate of 75%, a scaling simulation calculation revealed that even with Globaluf’s NFGuard 150 antiscalant dosing and no acid addition for pH adjustment, the CaCO3 scaling tendency was 106% (as shown in Figure 6). Considering water quality fluctuations, the risk of scaling was extremely high, which explains the severe scaling in A# and C#. The software calculation report also indicated that when the B# and D# units (which had not replaced their membranes) operated at a 50% recovery rate, their scaling tendency was not high, explaining why these two units did not experience severe fouling.

Figure 6: An example of a detailed membrane system scaling simulation report

Conclusion

From this case study, we can conclude that significant fluctuations in raw water quality pose substantial risks for NF units, which primarily function for desalination. Fluctuations in organic compounds in the water can lead to organic fouling of the membrane unit, while fluctuations in inorganic salts can cause fouling by difficult-to-dissolve inorganic salts. Therefore, close attention must be paid to influent water quality fluctuations, and the recovery rate of the membrane unit should be adjusted promptly.

While drastic fluctuations in system influent water quality are often uncontrollable, monitoring water quality changes and timely adjusting downstream processes are the most direct and effective ways to prevent RO fouling. For water quality fluctuations, the following measures can be adopted:

- Multi-dimensional Water Quality Monitoring: Implement comprehensive, multi-indicator monitoring of influent water quality. Beyond pH, conductivity, and temperature, incorporate parameters like online COD to detect water quality fluctuations in a timely manner, which can impact membrane systems.

- Strategic System Shutdown/Diversion: When significant fluctuations in influent water are detected, if conditions permit, the downstream membrane unit should be immediately shut down, or if the upstream equalization tank capacity is sufficient, the fluctuating water should be diverted for homogenization and regulation in the tank to prevent aggravated water quality from entering the membrane unit and causing fouling.

- Adjusting Operational Parameters: If it’s not possible to stop the downstream membrane unit, reduce the membrane unit’s influent flow rate (by reducing the number of operating sets) or lower the membrane unit’s recovery rate (concentration factor). This helps avoid the double impact of water quality and flow rate fluctuations, minimizing their effect on the membrane unit.

- Optimizing Chemical Treatment: When influent water has high hardness and alkalinity, posing a high scaling risk for the membrane treatment unit, consider appropriately adding acid to adjust the influent pH to reduce the risk of carbonate scale formation. Additionally, switching to an antiscalant with superior inhibition performance from a professional membrane chemicals manufacturer can prevent scaling by other difficult-to-dissolve inorganic salts. Globaluf’s own NFGuard 150, as demonstrated in this project, is designed to offer robust protection even under challenging conditions.

- Prompt and Effective Remediation: Once fouling has occurred, prompt and effective recovery measures should be taken. For organic and microbial fouling, sterilization and alkaline cleaning can be used. For difficult-to-solve inorganic salt scaling, acid cleaning should be applied. If necessary, offline cleaning or specialized cleaning agents from professional membrane chemicals manufacturers should be considered.

Globaluf: Your Trusted Partner in Water Treatment Resilience

At Globaluf, we apply these critical lessons and our extensive expertise to every water treatment plant we design and build, including providing essential maintenance and chemical solutions like our NFGuard 150 SC antiscalant. As a leading OEM water treatment and ODM water treatment provider based in China, we understand the nuances of diverse industrial applications, from industrial wastewater treatment to reclaimed water systems. Our commitment to top quality, customizable logo options, and advanced manufacturing technology ensures that our solutions are not only efficient but also resilient against real-world challenges like water quality fluctuations.

We offer a comprehensive range of products, including robust Commercial RO Systems, high-performance MBR Membrane Modules, and essential Water Treatment Components. Our solutions are proven in markets across Singapore, North America, Japan, South Asia, and the Middle East. With Globaluf, you gain a partner dedicated to delivering stable performance, cost-effectiveness, and peace of mind.

Ready to enhance your water treatment system’s resilience?

Contact our sales team today to discuss your specific needs and discover how Globaluf can provide tailored, top-quality solutions for your next project, from initial design to ongoing maintenance.

Email: sales@globaluf.com Visit us: www.globaluf.com

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf