Membrane Water Treatment Dosing Systems: A Comprehensive Guide from Globaluf

Introduction

Membrane water treatment technologies like microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) have become mainstream for desalination and water reuse. To ensure the optimal performance and longevity of these membrane systems, the precise and effective application of specialized chemicals is essential. At Globaluf, we’re dedicated to providing comprehensive chemical solutions and technical support for membrane systems worldwide. This guide breaks down the essential types of chemicals used in membrane water treatment and offers critical dosing tips.

Understanding the Essentials: Key Chemical Categories in Membrane Water Treatment

Membrane water treatment chemicals can be broadly classified into five main categories:

- Antiscalants: These are designed to control the precipitation and scaling of sparingly soluble inorganic salts on membrane surfaces. Antiscalants improve water production, enhance water quality, and reduce operational costs. They work by chelating ions, modifying crystal growth, dispersing microcrystals, and increasing salt solubility. Common types include inorganic phosphates, organic phosphates, and polycarboxylates.

- Biocides (Disinfectants): Biocides effectively kill bacteria, fungi, yeast, blue-green algae, and true algae, preventing biofouling of the membranes.

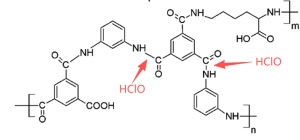

- Oxidizing Biocides: Sodium hypochlorite is a typical example, but can only be used in pretreatment or MF/UF membrane systems.

- Non-Oxidizing Biocides: Designed for RO systems, these can be added directly before the RO feed water for continuous or intermittent disinfection, or during chemical cleaning. Common types include chlorophenols, quaternary ammonium salts, organic sulfides, and organic bromine compounds. Isothiazolinone and DBNPA are widely used, with DBNPA offering excellent kill rates against bacteria and algae, decomposing into CO₂ and bromide ions without harmful residues.

- Reductants: Reductants neutralize residual chlorine or post-disinfection chlorine in the feed water to prevent oxidative damage to the membrane elements. Sodium bisulfite (NaHSO₃) is the most commonly used reductant.

- Cleaning Agents: These remove inorganic scales, biofilms, and organic matter from membrane surfaces. Cleaning agents are divided into acidic and alkaline types, including organic acids, inorganic acids, caustic soda, surfactants, and specialized proprietary formulations.

- pH Adjusters: These control the pH of the RO feed water. Hydrochloric acid (HCl) is used to lower the pH, reducing the risk of CaCO₃ and calcium phosphate scaling. Sodium hydroxide (NaOH) is used to increase the pH to enhance the rejection of boron and silicon, or to alter the state of carbon dioxide for removal by the RO membrane.

Key Considerations for Chemical Dosing in Membrane Systems

When selecting and dosing chemicals for membrane systems, consider these critical principles:

- Comprehensive Water Analysis: Determine the types and dosages of chemicals based on raw water hardness, alkalinity, sulfate, fluoride, silica, iron, SDI values, and microbiological indicators.

- Compatibility Verification: Avoid chemical reactions between different agents that can lead to precipitation, inactivation, or membrane system contamination.

- Precise Dosing Control: Use metering pumps and online sensors (e.g., pH meters, ORP probes) for closed-loop control.

- Economic Evaluation: Balance chemical costs with the benefits of extended membrane life, prioritizing cost-effective solutions.

Essential Dosing Tips

Here are key dosing recommendations for specific chemical types:

Antiscalants

- Water Quality Specificity: Select antiscalants based on water quality, especially for high-silica, high-calcium sulfate, high-hardness, or high-heavy metal waters.

- Dosage Calculation: Determine the dosage based on water quality indicators, using too little can cause scaling, and too much can cause membrane fouling.

- Cationic Polymer Compatibility: Perform compatibility tests with cationic polyelectrolytes to prevent membrane fouling due to incompatible chemicals.

- Minimum Concentration: Most antiscalants require a minimum concentration of 10%; do not dilute more than 10 times.

- RO Permeate Dilution: Use RO permeate to dilute antiscalants to prevent contamination or oxidation.

- Shield from Sunlight: Protect antiscalant dosing systems from sunlight to prevent biological contamination.

- Proper Storage: Store in a sealed container indoors, and prepare solutions weekly.Antiscalant Dosing Calculation Formula:

Notes:

x — Actual output of the dosing pump, liters per hour (L/h)

Q — Feed water flow rate, tons per hour (T/h)

a — Dosing rate, grams per ton (ppm, g/T)

V — Volume of each batch of prepared solution, liters (L)

1000 — Unit conversion factor, grams per kilogram (g/kg)

ρ — Density of the scale inhibitor, kg/L

U — Volume of stock solution to be added, liters (L)

Reductants

- Residual Chlorine Control: Ensure residual chlorine is less than 0.1 ppm before the membrane when using oxidizing biocides upstream. For new membrane elements, keep residual chlorine below 0.05 ppm.

- ORP Monitoring: If a residual chlorine meter is unavailable, maintain the ORP value below 220 mV.

Biocides

- Sodium Hypochlorite: Maintain a residual chlorine concentration of 0.1 to 0.3 ppm upstream of the reductant injection point for effective disinfection.

- Isothiazolinone: Use continuous injection for optimal results, maintaining a pH range of 4–8.

- DBNPA: Avoid contact with reducing agents, and use pulse dosing.

- Alternating Biocides: Switch biocide types periodically to prevent microbial resistance.

- Preparation Frequency: Prepare non-oxidizing biocide solutions every 2–3 times per week due to their rapid hydrolysis rate.

Cleaning Agents

- Compatibility: Ensure that the cleaning solution is compatible with the membrane element being cleaned.

- Maintain permeate flow: Ensure that the cleaning agent keeps the membrane wet to allow for a full cleaning

- Use High-Quality Acids: Use only high-grade hydrochloric acid to prevent oxidation damage from chlorine.

Globaluf: Your Partner in Membrane Water Treatment

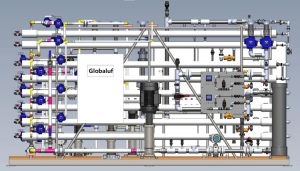

Globaluf is a global leader in membrane specialty chemicals, pioneering the development and production of dendritic polymer antiscalants. We are committed to providing green membrane treatment chemicals and full-process chemical and technical support for membrane systems. Our products include antiscalants, non-oxidizing biocides, and membrane-specific cleaning agents.

Conclusion:

Proper chemical treatment is vital for maintaining the efficiency and lifespan of membrane water treatment systems. Contact Globaluf today at sales@globaluf.com to learn more about our comprehensive chemical solutions and technical support for your membrane system.

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf

Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance