Key Parameters at RO Feed Water – The First Line of Defense in RO Desalination

Introduction

In any reverse osmosis (RO) desalination plant, ensuring optimal feed water quality is essential to safeguard the efficiency and lifespan of the RO membranes. Monitoring these parameters isn’t just good practice; it’s crucial to successful operations.

Here’s a detailed breakdown of the 10 essential parameters every operations team should monitor at the RO feed:

1️⃣ Temperature – Performance Driver

Why it matters: Temperature directly affects membrane permeability and the rate of water recovery.

Impact: Lower temperatures reduce flux, while higher temperatures may increase the risk of scaling.

Management tip: Adjust operating pressure and cleaning intervals based on seasonal temperature changes.

2️⃣ pH – Chemical Balance Enabler

Why it matters: pH influences coagulant efficiency, scale formation, and chemical dosing.

Control range: Typically maintained between 6.5–8.0, depending on treatment goals.

Challenge: Fluctuations can affect treatment efficiency, requiring careful monitoring and adjustment.

3️⃣ Conductivity (or TDS) – Salinity Indicator

Why it matters: Conductivity reflects the total ionic content in the feed water, impacting osmotic pressure.

Target value: Aim for levels compatible with membrane specifications to ensure optimum performance.

Solution: Regularly calibrate sensors for accurate readings and adjust as needed.

4️⃣ Turbidity – Clarity Indicator

Why it matters: High turbidity can overload pretreatment systems, leading to membrane fouling.

Impact: Poor pretreatment results in faster fouling and reduced flux.

Monitor: Implement real-time turbidity sensors for proactive management.

5️⃣ SDI (Silt Density Index) – Fouling Predictor

Why it matters: SDI is a key indicator of potential membrane fouling from particulates.

Ideal values: SDI < 3 is recommended for RO safety.

Strategy: Use effective pre-filtration methods to maintain ideal SDI levels.

6️⃣ Hardness – Scaling Contributor

Why it matters: Hardness can lead to scale formation, affecting membrane performance.

Control: Utilize softening or anti-scalant measures to mitigate scaling risks.

Monitoring: Regular testing and adjustments are necessary for optimal treatment.

7️⃣ Alkalinity – Buffer Capacity

Why it matters: Alkalinity involves HCO₃⁻ and CO₃²⁻ ions, which can form scaling compounds like CaCO₃ or MgCO₃ with divalent ions, affecting the membrane if concentrations exceed solubility limits.

Caution:High Alkalinity: Without pH adjustment, increased pH on the RO concentrate side can lead to scaling.Low Alkalinity: Over-acidification may cause feed water to damage membranes due to low pH.

Management: Adjust pH using acids to convert HCO₃⁻ to CO₂, reducing CO₃²⁻ concentration. Implement softening pretreatment to remove Ca²⁺/Mg²⁺.

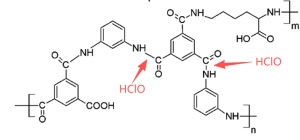

8️⃣ Free Chlorine – Biofouling Control

Why it matters: Chlorine helps control biological growth but must be neutralized before RO membranes.

Caution: Excess chlorine can lead to irreversible membrane damage.

Solution: Monitor ORP to ensure proper disinfection without risking membrane integrity.

9️⃣ ORP (Oxidation-Reduction Potential) – Disinfection Health Check

Why it matters: ORP provides insight into the presence and strength of disinfectants like chlorine.

Balance: Low ORP increases biofouling risk; high ORP risks RO damage if not neutralized.

Practice: Continuously monitor and adjust treatment processes for balanced ORP levels.

0️⃣ Oil – Contaminant Threat

Why it matters: Oil adheres to membranes and is challenging to clean, risking long-term damage.

Sources: Industrial discharge and environmental factors can introduce oils.

Detection: Employ oil sensors at feed water intake points for effective management.

✅ Why Feed Water Monitoring Matters

In regions relying heavily on RO desalination, feed water quality can change due to:

- Seasonal variations

- Industrial activities near water sources

- Environmental conditions

By continuously monitoring and adjusting treatment processes, operators can:

- Extend membrane lifespan

- Reduce chemical consumption

- Prevent unplanned downtime

- Ensure sustainable, safe water production

Final Reflection: Start Strong to Finish Clean

In RO desalination, monitoring feed water is not just an operational step; it’s the essential first barrier of control. Proactive management of these parameters ensures efficient and reliable water production.

Have you faced any unique feed water challenges in your plant? Share your insights with us now!

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf