How to Build a Complete Bottled Water Production Line: A Comprehensive Guide

Introduction

Thinking of entering the bottled water industry? This guide breaks down the essential steps and equipment needed to establish a successful small-scale production line, covering everything from water treatment to packaging.

Bottled mineral water and purified water are everyday consumer products, especially popular during the hot summer months. The high demand has spurred many entrepreneurs to consider investing in a water bottling plant.

Setting up a water plant is a long-term project that requires careful planning. You’ll need to obtain the necessary permits, secure a suitable water source and factory location, and, most importantly, acquire the right equipment and personnel. While other aspects can be adapted as needed, equipment selection demands careful consideration of production capacity, price, and after-sales service. So, what equipment is typically included in a small-scale bottled water production line, and what is the approximate investment?

1. Water Treatment Equipment: Ensuring Water Purity

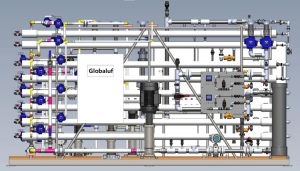

Water treatment equipment is crucial for deeply filtering the raw water, ensuring it meets the required drinking standards for mineral or purified water. Different water treatment solutions are needed depending on the raw water composition. Common equipment includes ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) systems.

- Mineral Water/Spring Water Production Line: If the raw water is mineral-rich spring water or mineral water, it’s important to preserve these beneficial components. Mineral water contains specific minerals meeting defined national standards, while spring water may contain fewer. In this case, hollow fiber ultrafiltration membranes are often used. This process effectively removes impurities while preserving the water’s essential minerals. The filtration system investment for this type of line is generally lower.

- Purified Water Production Line: If using groundwater or well water to produce purified water, the taste may be less complex than mineral or spring water, but the purity is significantly higher. Purified water production lines typically use reverse osmosis membranes, which effectively remove almost all impurities. However, this comes with a higher equipment investment. Since RO membranes have smaller pores, they are more prone to damage, requiring more advanced pretreatment systems to protect the RO membrane and extend its lifespan. Using RO water treatment creates the highest quality purified water.

2. Bottle Blowing and Filling Equipment: Efficient and Hygienic Core

After the water treatment system, the purified water enters the filling system. Bottles can be purchased directly from suppliers, or you can choose to equip a bottle blowing machine to make your own, allowing for better cost control and bottle design.

Currently, the mainstream filling equipment is the three-in-one filling machine, which integrates rinsing, filling, and capping functions, significantly improving production efficiency. To ensure hygiene and safety, the capping section is usually equipped with disinfection facilities.

3. Packaging Equipment: Enhancing Brand Image

After filling, the bottles need to be labeled. You can choose the appropriate machine according to the factory’s packaging requirements. In addition, you can configure a laser coding machine to print production dates and batch numbers on the bottles, as well as a film wrapping machine for easy transportation and sales.

Small Bottled Water Production Line Investment Cost Analysis

The above outlines the primary equipment included in a small bottled water production line. When purchasing equipment, water plants should fully consider their production needs and budget, and choose the most cost-effective configuration.

So, how much does it cost to set up a small mineral water plant?

For a small purified water production line that produces 2,000 bottles per hour, the investment is approximately between 25,000 35,000 USD. This includes water treatment equipment, filling equipment, and packaging equipment.

If you have any questions about other equipment or more detailed investment budgets, feel free to contact us below. We will be happy to assist you.

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

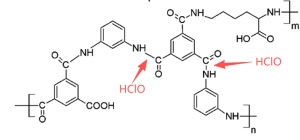

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf