Comprehensive Guide to Pure Water Treatment Equipment: Media Filters, Ultrafiltration, Reverse Osmosis and More

Introduction

Water treatment is crucial for purifying contaminated industrial wastewater and raw water to meet national water quality standards. As water is deeply interconnected with social production and daily life, the water treatment industry plays a significant role in ensuring clean and safe water supply. This guide explores the various equipment used in pure water treatment, showcasing advanced technologies and techniques for achieving superior water quality.

I. Pre-treatment Equipment

1. Media Filters

Overview

Media filters employ various filtration media to remove suspended solids from water under pressure, achieving a turbidity often reaching below 3 NTU. Common materials include quartz sand, anthracite coal, and manganese sand, suitable for turbidity removal, water softening, and pre-treatment for demineralization. The system comprises a filter body, related piping, and valves, featuring components such as filter vessels, water distribution components, and air vent valves.

Working Principle

- Filtration Process: Raw water travels through a multi-layer water distributor in a near-laminar flow, trapping impurities within the media layer. Mushroom-shaped collectors at the bottom ensure efficient filtration at high flow rates.

- Backwash Process: Regular backwashing is pivotal in maintaining filter efficiency, where clean, filtered water flows backward through the filter unit, lifting the media layer to discharge impurities.

Common Media Filters

- Multi-Media Filters (MMF)

Consisting of anthracite-quartz sand-magnetite filters, designed based on density differences and raw water quality. - Activated Carbon Filters (ACF)

Effective in removing color, taste, and organic matter through adsorption, reducing suspended solids and COD significantly. - Iron and Manganese Filters

Filled with refined manganese sand, ideal for groundwater with high iron and manganese content.

2. Disc Filters

Overview

Compact with high filtration accuracy, disc filters are increasingly preferred in large-scale ultrafiltration applications.

Working Principle

Thin discs stack within a cartridge, forming filtration channels that efficiently trap impurities. Backwashing can be manual or automatic.

Advantages of Disc Filters

- Stable filtration effect with simple operation and maintenance

- Long lifespan exceeding 10 years

- Low system operating costs

3. Precision Filters (Cartridge Filters)

Overview

Also known as security filters, they remove fine particles, using cartridges made from polypropylene melt-blown fiber or wound PP cotton, suitable for small ultrafiltration units.

Working Principle

Fiber compression changes pore size to trap particles. Automatic backwash releases compression, flushing impurities.

II. Ultrapure Water Treatment Equipment

4. Ultrafiltration (UF)

Overview & Principle

Utilizes physical sieving under pressure to separate water and small molecules, with pore sizes ranging from 10-100nm.

Basic Principle

Under pressure, raw liquid flows across the membrane surface. Water and small molecules pass through the membrane’s micropores to become permeate, while substances larger than the pore size are retained on the feed side as concentrate. This achieves purification, separation, and concentration of the raw liquid.

UF Classification and Characteristics

UF membranes are primarily classified into spiral wound, plate-and-frame, tubular, and hollow fiber types. Hollow fiber is widely used domestically, characterized by lacking a membrane support structure, relying on the fiber tube’s strength to withstand pressure. Hollow fiber membranes are further divided into inside-out and outside-in configurations.

Inside-out hollow fiber membranes are advantageous due to their large effective membrane area per unit volume and small footprint.

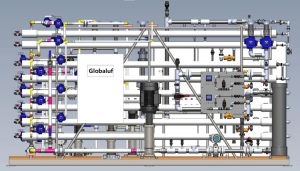

5. Reverse Osmosis (RO)

Overview

Reverse osmosis is a membrane process that separates liquid mixtures by selectively passing solvent (typically water) through a membrane while retaining ionic substances. It uses a pressure difference across the membrane to overcome osmotic pressure, allowing the solvent to pass.

Separation Mechanism

The selective permeability of the RO membrane is related to the dissolution, adsorption, and diffusion of components in the membrane. This depends on membrane pore size, structure, chemical and physical properties, and interactions between the components and the membrane. Chemical factors (membrane characteristics) dominate the separation process.

Applications

RO is used for brackish water and seawater desalination, pure water production, and separating mixtures difficult to separate by other methods. Industrial applications include:

- Seawater desalination

- Drinking water production

- Pure water production

6. Anion and Cation Exchangers

Overview

Exchangers resemble multi-media filters in appearance, often with a rubber lining for corrosion protection. They are filled with various anion and cation exchange resins, often using strong alkaline anion exchange resins and strong acid cation exchangers.

Working Principle

- Strong Acid Cation Exchange Resin (001×7)

When the resin contacts water, cations in the water exchange with H+ ions on the resin, removing cations and releasing hydrogen ions.

- Strong Base Anion Exchange Resin (201×7)

When the resin contacts water, anions in the water exchange with OH- ions on the resin, removing anions and releasing hydroxide ions.

7. Mixed Bed Ion Exchangers

Overview

Used to produce high-purity water. Typically placed after anion and cation exchangers, or downstream of electrodialysis or RO. Used in electronics, pharmaceuticals, paper-making, chemicals, and nuclear industries, as well as for purifying sugar solutions, glycerol, and polyols.

Working Principle

A mixed bed contains anion and cation exchange resins mixed thoroughly in a 2:1 ratio. Anions and cations are adsorbed onto the resins, and the exchanged H+ and OH- ions react to regenerate water, achieving ultrapure water production.

8. Electrodeionization (EDI)

Overview

EDI, or electrodeionization, is a technology for producing pure water without using acids or alkalis. Relying on electricity, it continuously produces high/ultrapure water without chemical consumption. It’s a next-generation, green technology that replaces traditional mixed beds for deep demineralization.

Working Principle

In EDI, ions in the feed water are removed by exchange through a resin layer, purifying the water. Voltage applied across the membrane stack electrolyzes water molecules into hydrogen and hydroxide ions to continuously regenerate the resin. Ions exchanged are migrated to the concentrate chamber under the influence of the electric field.

Advantages Compared to Mixed Bed Technology

Harmless Chemistry

- Continuous regeneration using electricity, eliminating corrosive chemicals.

- Requires minimal cleaning if the upstream RO system operates normally.

- No investment in chemical regeneration equipment such as alloy valves, pipes, pumps, and chemical storage.

Continuous Regeneration

- Eliminates the need for backup ion exchange equipment.

Simple Startup/Operation

- Eliminates complex mixed bed regeneration steps.

- Fewer valves, automated operation, and ease of use.

Convenient Module Replacement

- Typical module lifespan exceeds 3-5 years.

- Easy storage and replacement of EDI modules.

III. Auxiliary Equipment

9. Flocculation

Small colloidal ions (<5 microns) in raw water carry electric charges and repel each other, making sedimentation or pre-filtration difficult. A flocculant is added to neutralize the charge, causing the particles to agglomerate for removal. Common flocculants include ferric chloride, aluminum sulfate, and alum. pH should be 6-8.4 for ferric chloride and 5-7.5 for aluminum sulfate. Small amounts of polymer coagulant aids, such as polyacrylamide, can be added to improve flocculation.

10. Degasifier (Decarbonator)

Overview

A forced-draft, atmospheric-pressure steel structure device. Typically installed after cation exchangers or RO systems to remove free CO2 decomposed from acidic water using air.

Working Principle

Acidic water is introduced at the top, sprayed mechanically, and flows over a packing layer with a large surface area. Air passes upward in the opposite direction, stripping free CO2 from the water, which mixes with the air and is discharged at the top. Typically, residual CO2 after this process will not exceed 5mg/L.

Explore effective water treatment solutions with our advanced equipment and expert guidance. Contact us today to elevate your water quality to meet top standards.

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

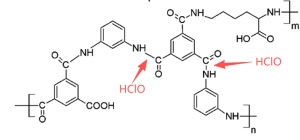

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf

Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance