Beyond the Basics: Advanced Reverse Osmosis System Design by Globaluf

Introduction: Engineering Purity at Its Peak – The Art of Advanced RO Design

In the dynamic world of water treatment, a standard Reverse Osmosis (RO) system often suffices for basic purification needs. However, for industries demanding stringent water quality, battling challenging feed water, or striving for optimal cost-efficiency, advanced RO system design becomes not just beneficial, but critical. At Globaluf, we transcend conventional solutions, leveraging our profound expertise and cutting-edge manufacturing capabilities to engineer RO systems that deliver superior performance, extended longevity, and unparalleled economic value.

This article delves into the sophisticated nuances of RO system design, showcasing how Globaluf, as a leading OEM/ODM water treatment plant manufacturer from China, addresses the intricate balance between initial investment (CAPEX) and long-term operational costs (OPEX), ensuring the lowest total cost of water for our global clients.

The Fundamental Dichotomy: Balancing CAPEX and OPEX

Every RO system design inherently navigates a fundamental trade-off:

- Minimizing Capital Costs (CAPEX): This often involves maximizing system flux and minimizing the number of membrane elements and pressure vessels. While reducing upfront investment, it can lead to higher operational challenges if not balanced correctly.

- Minimizing Operational Costs (OPEX): This typically implies a lower system flux, a higher number of elements and vessels, and a preference for low-energy membranes. This approach prioritizes long-term savings through reduced energy consumption, less frequent membrane replacement, and lower chemical usage.

Globaluf’s advanced design philosophy aims to achieve your required permeate quality at the lowest total cost of water, meticulously balancing these two crucial aspects through precise engineering and innovative solutions.

Navigating Complexity: Variables and Design Considerations

The real challenge in RO design lies in managing a multitude of variables. Our design process meticulously considers:

1. Feed Water Characteristics: The Starting Point

The quality of the raw water dictates the complexity and robustness of the system.

- Key Variables: Temperature, pH, Silt Density Index (SDI), Turbidity, and Salinity are paramount. For instance, high SDI indicates a greater potential for membrane fouling, demanding more aggressive pre-treatment.

- Fouling Potential: Identifying and mitigating the potential for organic fouling, scaling (e.g., silica, calcium carbonate), and biofouling drives decisions on membrane type and system configuration.

2. System Operating Variables: Optimizing Performance

These parameters are carefully controlled to ensure optimal system performance and membrane lifespan.

- Element Flux & Feed Flow: Maintaining ideal flux rates across individual membrane elements is crucial to prevent premature fouling and ensure consistent permeate quality.

- Differential Pressure: Monitoring pressure drop across membrane arrays helps detect fouling and guide cleaning cycles.

- Element & System Recovery: Optimizing water recovery while safeguarding membrane integrity.

- Operating Pressure: Selecting the right operating pressure to achieve desired permeate quality efficiently, often influenced by membrane type (e.g., lower pressure for energy-efficient membranes).

Advanced Design Strategies by Globaluf: Engineering for Excellence

Beyond basic calculations, Globaluf employs sophisticated design methodologies to overcome complex challenges and deliver superior RO solutions.

3. Mastering Flux Balance: Extending Membrane Life and Efficiency

Maintaining an even flux distribution across all membrane elements within an array is key to preventing localized fouling and maximizing membrane lifespan. Globaluf utilizes several advanced techniques:

- Stage-wise Pressure Management:

- Permeate Backpressure: Applying a controlled backpressure to the permeate of the first stage can help balance flux, especially in two-stage systems.

-

- Inter-Stage Boost Pumps: Increasing feed pressure between stages can significantly enhance flux distribution and overall system performance, particularly in multi-stage seawater desalination (SWRO) systems.

- Multi-Element Hybrid Arrays: This involves strategically deploying different types of RO elements (e.g., varying water permeability or fouling resistance) within the same array. This approach can optimize flux balance, improve permeate quality, and even adjust the permeate TDS.

- Internally Staged Design (ISD) RO Array: A highly advanced method, particularly effective in SWRO and municipal drinking water RO/NF systems. ISD involves using multiple RO element types within a single pressure vessel. This allows for fine-tuned control over element flux and optimizes energy consumption by ensuring each membrane operates at its most efficient point. It can also minimize post-treatment chemical addition by precisely managing permeate quality.

4. Achieving Desired Permeate Quality: Tailored Solutions

Meeting specific product water quality targets often requires more than a single-pass RO system. Globaluf offers various configurations:

- 2-Pass RO Systems: For applications demanding ultra-high purity, such as boiler feedwater or semiconductor rinse water, a second RO pass ensures exceptional purity levels by removing residual impurities that passed the first stage. This often involves inter-pass pH adjustment (e.g., with NaOH) to enhance rejection of challenging ions like alkalinity and boron.

- RO with Feed Water/Permeate Blending: Common in drinking water plants, this involves blending a portion of the raw (or partially treated) feed water with the RO permeate. This cost-effective strategy can increase overall system throughput, adjust final water characteristics (e.g., mineral content, pH), and minimize post-treatment chemical usage, especially for managing disinfection byproduct formation potential (DBPFP). This approach can lead to significant CAPEX and OPEX savings.

- Partial 2nd Pass & Split Permeate Designs (especially for SWRO): To optimize CAPEX and OPEX in seawater desalination plants producing municipal drinking water, Globaluf implements designs where only a portion of the first-pass permeate is treated by a second pass.

- Split Permeate SWRO: This involves withdrawing permeate from both ends of the first-stage pressure vessels. The “front permeate” (typically lower in salinity) can be directly blended into the final stream, reducing the load on the second pass and optimizing energy consumption. Many split permeate SWRO systems integrate ISD for enhanced performance.

Optimizing Energy Efficiency: The Role of Energy Recovery Devices (ERD)

Energy consumption is a primary operating cost for RO systems, especially in seawater desalination. Globaluf prioritizes energy recovery to minimize your environmental footprint and maximize your savings.

- How ERDs Work: ERDs capture residual hydraulic energy from the high-pressure concentrate (brine) stream leaving the RO system and transfer it back to the incoming feed water, significantly reducing the energy required by the main high-pressure pump.

- Types of ERDs: We integrate various types of ERDs, including pressure exchangers (e.g., ERI PX devices, DWEER Work Exchanger) and turbochargers (e.g., FEDCO Turbine), selecting the most appropriate technology based on system size, pressure, and specific application. ERDs are used in virtually all modern SWRO plants and increasingly in larger BWRO systems.

- Cost Savings: Implementing ERDs can lead to substantial OPEX savings, making large-scale RO projects more economically viable.

Globaluf: Your Expert Partner for Advanced RO Solutions

The complexity of advanced RO system design demands not just theoretical knowledge but also practical experience, state-of-the-art manufacturing, and a deep understanding of customer-specific needs.

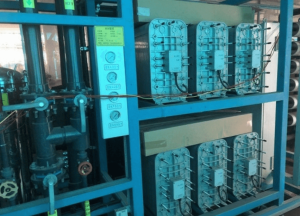

- Unmatched Expertise: Our team comprises seasoned water treatment experts proficient in membrane water treatment processes, including ultrafiltration (UF), nanofiltration (NF), and reverse osmosis, from initial concept to full-scale operation. We utilize advanced simulation software like DuPont Water Solutions’ ROSA to ensure every design is rigorously optimized.

- Quality & Reliability: At Globaluf, located in China with a big manufacturing site and advanced manufacturing technology, we are committed to top quality. Our meticulous production processes and stringent quality control measures ensure that every system is built to excel, addressing any concerns regarding product stability and durability from Chinese suppliers.

- Customization & OEM/ODM Excellence: We specialize in customizable logo and rare style solutions, serving international OEM manufacturers, large enterprises, and distributors. Whether you need a complete pure water treatment plant, a wastewater treatment plant for reuse (ZLD), or seawater desalination treatment solutions, our B2B, OEM, and ODM models ensure a perfect fit for your business strategy.

- Global Presence & Support: With a strong export record to Singapore, North America, Japan, South Asia, and the Middle East, we provide efficient communication, professional project management, and reliable after-sales support globally.

Conclusion: Pushing the Boundaries of Water Purity with Globaluf

Advanced RO system design is a sophisticated discipline that blends scientific principles with engineering innovation. At Globaluf, we are continuously pushing the boundaries of water purification technology, offering solutions that are not only highly efficient and reliable but also environmentally sustainable and economically advantageous.

When facing challenging water sources, stringent purity requirements, or the need for optimized operational costs, trust Globaluf to engineer an advanced RO system that exceeds your expectations.

Elevate Your Water Treatment Capabilities with Globaluf’s Advanced RO Solutions!

Unlock the potential of cutting-edge RO technology for your next project. Our experts are ready to collaborate on a design that perfectly aligns with your quality standards, budget, and sustainability goals.

Request a Customized Quote & Consultation for Your Advanced RO System

Discover More: Explore Globaluf’s Full Range of Water Treatment Plants Learn about our Pure Water Treatment Solutions

Request a Quote

Fill out the form below to discuss your water treatment needs. Our experts will get back to you within 24 hours.

You may also be interested in:

What is a Membrane CIP System? The Ultimate Guide for Plant Managers and Technicians

Understanding Scaling and Backpressure in Reverse Osmosis Systems

How to Purify Borehole Water for Drinking

What is Hard Water and How to Remove Hardness From It?

The Hidden Threat: Your Expert Guide to Preventing RO Membrane Biofouling

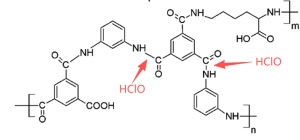

The Silent Killer of RO Systems: A Complete Guide to Preventing Membrane Oxidation

How to Desalinate Sea Water: The Ultimate Guide to SWRO Technology

Understanding RO Membrane Scaling: Causes, Effects, and Prevention Strategies

Navigating Water Quality Fluctuations: Globaluf's Expertise in Safeguarding Membrane System Performance